By Terry Rayner

By Terry Rayner

In a previous post Not Understanding Value Can Cost Printers More Than Customers, I discussed the meaning of Value as seen through the eyes of a Lean practitioner, now I want to address waste so that you can get out into your plant and start making real change.

Lean Identifies eight categories of waste that you will need to review and address if you are increase value within your business. As increasing value will result in an increase in profits…

…and reducing waste = an increase in value!

The eight categories of wastes are:

The eight categories of wastes are:

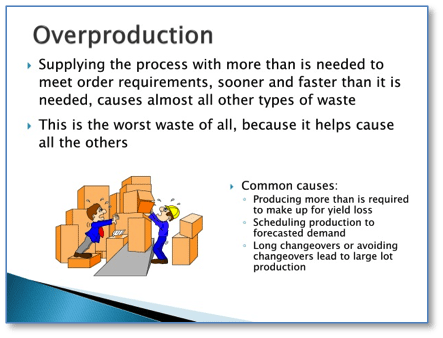

- Overproduction

- Inventory

- Transportation

- Motion (operations)

- Defects / Quality

- Waiting

- People Skills

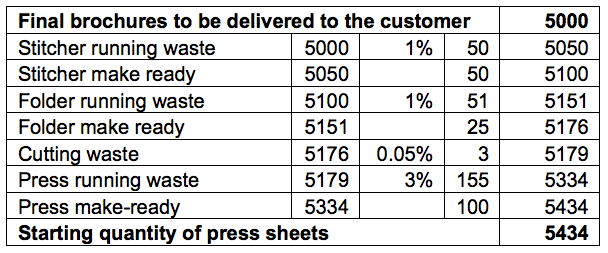

To produce a printed product we go through many steps; for the example of overproduction let’s start in the office. The sales rep brings in a quote request for a 5,000 16-page, 8.5 x 11 saddle-stitched brochures, and the estimator builds an estimate based on the standards that have been entered into the estimating system.

These standards allow for spoilage at each level of production (To simplify this example I have made up the waste numbers/percentages listed):

- Press make-ready waste: 100 sheets

- Running waste: 3%

- Post press cutting waste: 0.05%

- Folder make-ready waste: 25 sheets

- Folder running waste: 1%

- Stitcher make-ready waste: 50 brochures

- Stitcher running waste: 1%

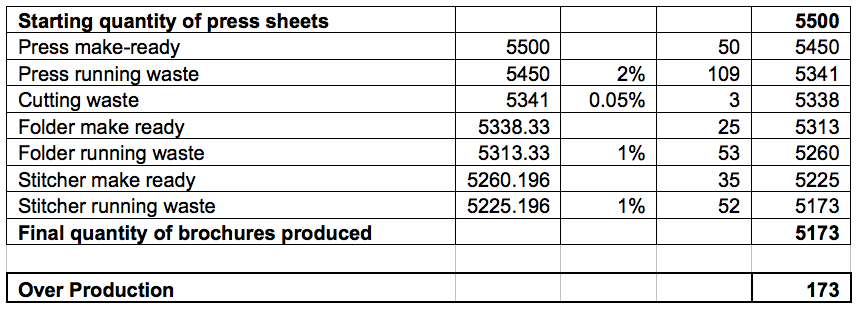

For this example of overproduction I am going to assume that the purchasing agent rounded the paper order up to 5,500 press sheets and that is what issued to the pressroom. Let’s also assume that the press make-ready was complete after 50 press sheets and the press running waste was only 2%.

For this example of overproduction I am going to assume that the purchasing agent rounded the paper order up to 5,500 press sheets and that is what issued to the pressroom. Let’s also assume that the press make-ready was complete after 50 press sheets and the press running waste was only 2%.

In addition at each step of processing all of the press sheets received from the previous function are processed – The table now looks like this:

While 173 extra brochures does not seem a lot of “overs,” however it is 3% of the order.

173 brochures that the customer is not paying for – Therefore, it has no value (100% waste)

Now let’s look at the impact of this overproduction:

If this happens on a regular basis there will be literally thousands of FREE over’s being produced each day, using resources that could have been used to produce product that would have been billable! Adding value!

When you next walk through your operations start looking at skids with extra boxes stacked upon them and asking yourself: “Is this overproduction waste?”

Don’t wait! Investigate and get your production team together; talk to them about overproduction and what their ideas are for reducing it.

Perhaps it will be apparent that your estimating standards need changing to allow less spoilage waste!

Perhaps you will need to examine your standard operating procedures and add new procedures that stop over-producing at each process stage if the allowed amount of spoilage has not been used!

I know what you are saying… we won’t be able to stop the pressmen or folder operators running these few extra sheets. But you must.

“Look at it this way. Let’s assume that you control this and with the “found capacity” at each stage you are able to produce more “saleable product” each day. At the end of the month your cost of sales will have decreased, which in turn will increase your gross profit.”

“Look at it this way. Let’s assume that you control this and with the “found capacity” at each stage you are able to produce more “saleable product” each day. At the end of the month your cost of sales will have decreased, which in turn will increase your gross profit.”

In an industry where profit margins are slim, adding 1% to your gross margin that drops to your bottom line could equate to a 10% increase in your profits!

Click here to download an easy to use PowerPoint presentation (originally authored and posted by Harold Philbrick) to learn more about the eight-wastes and to use as a training tool for your teams!

Thanks to people like Harold who have shared their ideas and documented them, you can start implementing Lean without having to re-invent the wheel… download this presentation, read it, understand it, and implement programs to eliminate all wastes in your business!

With over 25 years of print management experience Terry Rayner is a Lean Thinking Guru. Using his blend of customer focused philosophies and continuous improvement methodologies he has led companies through major changes to emerge re-energized. Certified in Lean Six Sigma Processes for manufacturing, office and sales environments he is relentless in his pursuit to eliminate wastes, which increase efficiencies and effectiveness; ultimately leading to higher customer satisfaction and significant profit growth.

Connect with Terry: Getleanthinking.com / LinkedIn / Twitter

2 Responses

this statement;

“173 brochures that the customer is not paying for – Therefore, it has no value (100% waste)”

Sez who ?

Most estimating system have settings for waste built in so, when the quote comes out with “needed sheets” – of course that is built into the quote, so, sorry, totally disagree that it has no value – that is the price of manufacturing. When you buy a can of tuna, do you really thing that the price of manufacturing waste as well as fulfillment, delivery, warehousing and other ‘no tuna fish related things” are not built in ?

I am all about monitoring waste – and declaring a war on waste – but to suggest this is not passed onto the person buying that print project is a bit naive.

Michael,

Thanks for the comment.

I am not saying that no spoilage allowance is included in a job and, therefore, the customer does not pay for this. What I am saying is that if the operators do not stop and continue to manufacture more product than is needed then the over-production/over-processing is waste (as the operator could have stopped and then less material would have been used and less time taken to produce the job).

The waste is the time and materials that were used to produce another 173 printed pieces that the customer is not going to pay for – but you the printer put time and energy into (resources) to make.

Do this hundreds (or thousands) of times per years and the hours and materials wasted becomes staggering.

Yes, you may have factored it in, and yes the customer may be paying for it in your selling price.

But. if you don’t do this then (don’t produce the extra 173 pieces):

1. You make more money (less waste)

2. If you get good at this you can sell your print for less than your competitors that are still running all the materials and wasting precious production time – and make the desired margin.

3. If you don’t do this and your competitor does you will probably eventually join the ranks of the 10,000+ printers that have gone out of business over the last 10 years and wonder why.

Lean Thinking challenges us work in new ways and to re-think what we have been doing for years.

I know that stopping and not overproducing is hard – if it was easy we would all be doing it!

However, the companies that persevere are the ones that will be profit leaders and won’t we all rather be working for a profit leader than a company fighting to survive?