Revolutionary 3D process turns conventional 3D printing upside down

Revolutionary 3D process turns conventional 3D printing upside down

by Ben Rutter

Are you ready to see the flyest step forward in 3D printing this year and quite possibly for a while to come? I hope you shouted a resounding “YES” at your computer, because I want you to be ahead of the pack when you talk about developments in the vast and diverse world of print.

For good or bad, when the masses think of print these days, they often think of 3D print. When you Google the word “print,” you see 3D print right up there at the top.

Of course we all know that print and 3D print are different. Very different. Well, the old 3D print and the new 3D print are different as well.

In fact, the new 3D print turns the concept of 3D printing on its head.

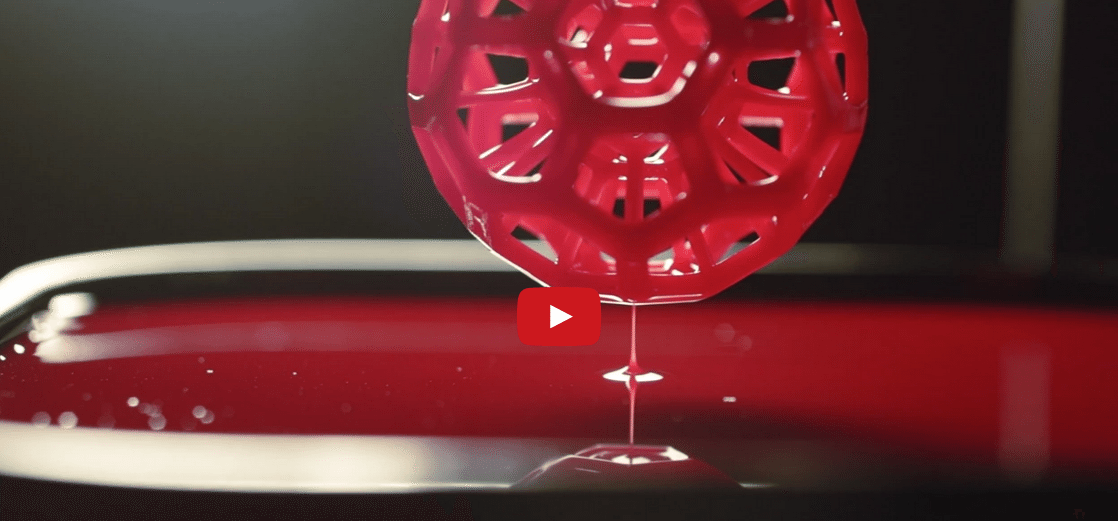

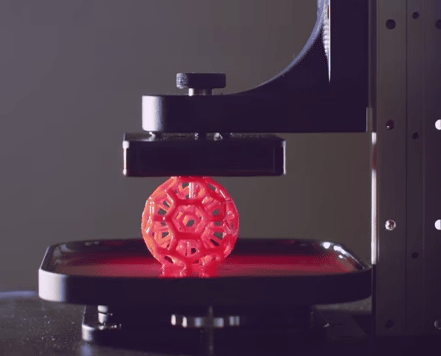

A North Carolina company named Carbon3D has produced a “Terminator 2”-inspired three dimensional printer, dubbed “CLIP.” And CLIP changes the entire premise of constructing a 3D printed object.

Previously, the most common form of 3D printing has been an additive process. The machine “prints” the object by constructing — with the material of your choosing — a shape that has been pre-engineered. The material is stacked (printed), layer by layer, until the desired item is created.

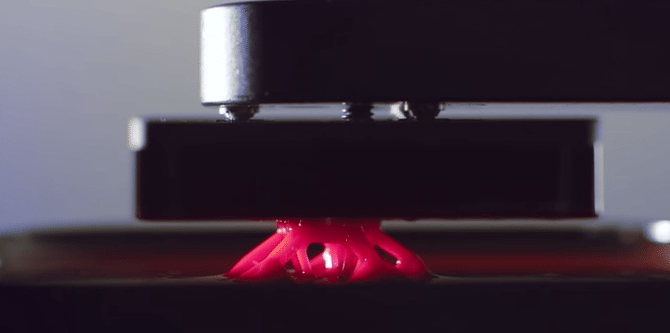

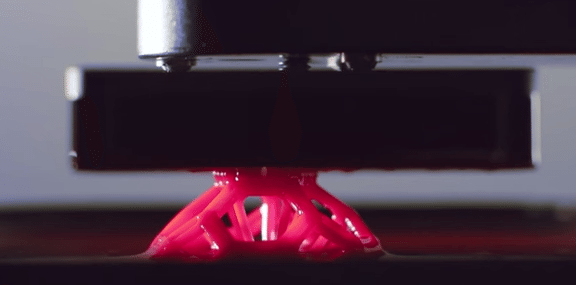

The wacky part about CLIP, though, is that the agglomeration process is reversed.

Creator Joseph DeSimone, says that the end of “Terminator 2” is what inspired his team to create this new process. The “aha” moment in the movie was when the T-1000 rises from a puddle of liquefied metal to form a menacing Robert Patrick.

With CLIP, objects are essentially printed in the same way.

The arm of the printer is dipped into a pool of colored resin, and slowly elevated, pulling with it your freshly printed item. Extraneous portions of the item, used to support the object as it emerges from the resin bath, are later cut away. Here’s the kicker; the company says the technique works 100 times faster and produces objects significantly stronger than ever before. In a test, it took CLIP seven minutes to produce a hollow geometric prism, a task which would have taken close to ten hours in a standard 3D printer. The strength and speed comes from a process which utilizes light and oxygen instead of pumping ink straight from a toner to the printer.

The machine has become something of a sensation, due to the Terminator references. And the company, Carbon3D, has become a household name in the tech realm due to being highlighted in a recent issue of the journal “Science.”

Here are links to other articles on the process.

Carbon3D is going about this in all the right ways too, which is awesome.

- First of all, they’re using viral marketing via social media. In fact, that’s how I learned about CLIP. I saw a GIF of the process, posted on photo-sharing websites Pinterest and (for the younger folk) imgur.

- Second, the 3D wave makes the concept fascinating to a broad group of young and older garage inventors.

- Third, by appealing to the technology in-crowd, the company is capitalizing on their audience’s desire to be among the first to know about head-turning new technology. With picture sharing, people see it, read about it, want it, and share it. With technology-based inventions, news spreads like those giant underground fungi. People want to share with others who “get it” — that is, who are worthy of this information. Asking an acquaintance if they’ve heard of CLIP is a test of sorts.

- Finally, the icing on the cake for anybody who had the pleasure of stumbling across CLIP is that it is associated with a movie most have seen, and can immediately relate to. You can discuss technology in the context of something you both understand, based on popular culture.

Launching a visual product in an emerging field, with a twist that is based in science fiction and movies, and a techno-addicted fan group doing your viral marketing… well, it’s brilliant. Of course, having an surprising and revolutionary product also helps in the busy and evolving world of 3D print.

Ben Rutter is a full time student and the fifth generation in his family to make his name in journalism and the printing industry. Ben covers the teen perspective of media and print for Print Media Centr. You can read more of his articles here.

Ben Rutter is a full time student and the fifth generation in his family to make his name in journalism and the printing industry. Ben covers the teen perspective of media and print for Print Media Centr. You can read more of his articles here.

One Response

Fascinating breakdown of the process. I think another advantage is it eliminates the surface striations that come with the additive 3D process.