Brian Rothschild has been a connection of mine on LinkedIn for quite a while, and he always has something lively and topical to add to the discussions he participates in throughout the platform. I was totally psyched that I would finally be able to meet him face to face at Graphics of The Americas, and he did NOT disappoint! His energy (even after a long drive that started before the sun came up) was contagious, and if I didn’t have to stay in my own booth I probably would have followed him around throughout the day. Luckily for me he took in a few seminars and came back to hang out with us, especially since my computer started acting up and I was only able to remain calm during my “Kernel Panic” knowing I had an Apple Genius on the way – bonus!

Brian Rothschild has been a connection of mine on LinkedIn for quite a while, and he always has something lively and topical to add to the discussions he participates in throughout the platform. I was totally psyched that I would finally be able to meet him face to face at Graphics of The Americas, and he did NOT disappoint! His energy (even after a long drive that started before the sun came up) was contagious, and if I didn’t have to stay in my own booth I probably would have followed him around throughout the day. Luckily for me he took in a few seminars and came back to hang out with us, especially since my computer started acting up and I was only able to remain calm during my “Kernel Panic” knowing I had an Apple Genius on the way – bonus!

It’s been some weeks since GOA but we continue to stay in touch. When the subject of 3D printing, stemming from a post on PMC, became a hot topic on LinkedIn, Brian went from “skeptic” to “believer” and I asked him to write about his experience. As usual, he delivered above and beyond and provided some amazing information in this post to share with all of us… and possibly convert a few more that 3D printing isn’t so far out of reach.

3D Printers – What I thought I knew, but know now.

About 2 years ago I received an invitation for a free subscription to PD&D Magazine (Product Design & Development). There was a very cool article about a 3D printer from Stratasys being delivered and setup, The 900MC Stratasys Fortus. This URL (http://tinyurl.com/cksbzty) will direct you to the images and logistics of receiving and installing the unit. For now, all you need to know is that it’s big, real big, and so was the price. However, I found the technology fascinating and started to follow its development and implementation.

Fast fast forward two years. I’m reading a discussion in one of many LinkedIn groups I follow in reference to a post from PrintMediaCentr about 3D printers, but this discussion is about desktop 3D printers and when we could expect to see them. Someone mentioned that “you could expect to see a desktop version in Staples by the end of the year”. And I laughed and thought…. “Not from what I’ve been reading… nope. Maybe in 5-7 years”, “not even if they cut the price in half tomorrow”

Boy, was I wrong. As it is today, not only could we expect to see these devices, they are already here. If you took the time to see the 900MC then you understand just how fast technology moves.

Now, take a look at this!

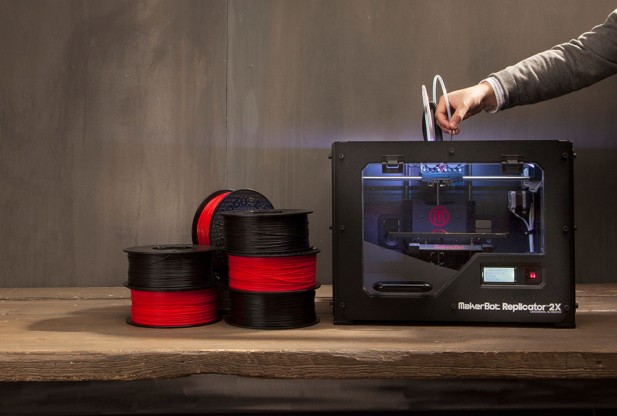

CES 2013: MakerBot Introduces New And Improved Replicator 3D Printer.

Televisions are often a hit at any CES event, with companies like LG, Samsung and Sony fighting to become the first to announce the latest in 3D or UltraHD displays. This year, much attention has been placed on another piece of 3D tech, the MakerBot Replicator 3D printer. 3D printing is steadily rising in the market with plenty of interest, and though current models are priced firmly outside the average consumers range, the possibilities for these printers are seemingly unending.

While the previous version of the Replicator 2 3D printer was capable of creating small figures measuring 410 cubic inches high, the new and improved Replicator can produce items about the size of a loaf of bread. Or, as excited MakerBot CEO Bre Pettis has explained, the new Replicator 2X can print “the world, and nothing’s bigger than the world.”

This Brooklyn-based company began in 2009 with the goal to make 3D printing not only reliable, but affordable as well. Makerbot now says they’ve continued to improve on their design, making significant leaps and bounds in only four years. The MakerBot Replicator 2X has the ability to make large, ABS prints more reliably than the original replicator. This new printer is aimed at those who want to push the boundaries of 3D printing, allowing for multicolor and even multi-material prints.

To help drive this new printer, MakerBot is also releasing MakerWare 1.1 software and firmware updates for existing printers and the new Replicator 2X. With this new software, users can drag the 3D models directly to the printer, as well as see their print in the colors they intend to use for the 3D object. While the previous version used an eco-friendly ABS material, the Replicator 2X uses a sturdier ABS filament and is capable of distributing it at a resolution of 100-microns.

“The redesigned thermal core and the improved alignment of the extruders really brings dual extrusion to a new level. It’s going to allow designers to stop thinking of how to print, and start thinking of what to print,” claims The Product Manager at MakerBot.

The company believes the advancements made by MakerBot will allow today’s children to become even better inventors and tinkerers. While a main goal of MakerBot is to make 3D printing affordable, it’s still priced outside the reach of the average consumer. Prosumers, on the other hand, likely won’t mind paying the $2,799 for the new Replicator 2X.

With this new printer, MakerBot has essentially handed over plenty of creative license to the experimenters, asking them to take this platform and run with it, creating what they will and testing the boundaries of 3D printing. In closing, If you’ve ever gone under the hood and tuned up a hot rod or rebuilt and engine or built a trebuchet from scratch, the MakerBot Replicator 2X is for you.

And it gets smaller. Much smaller!

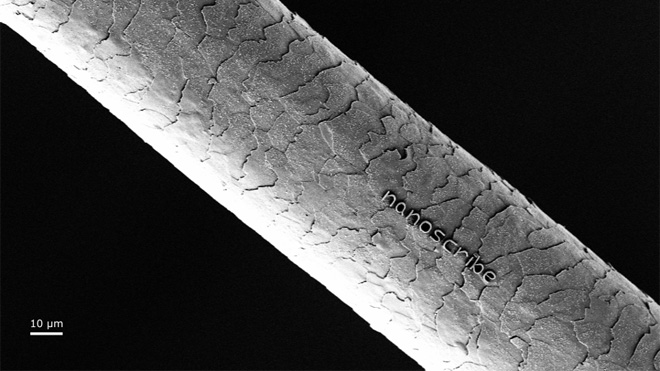

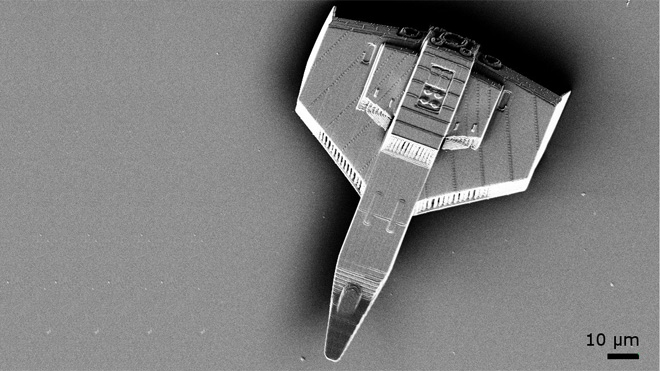

This month at Photonics West, the international fair for photonics in San Francisco, Nanoscribe GmbH introduced a micrometer scale 3D printer. With this technology, tiny structures at a nanometer size can be fabricated. According to the Germany based company, it is the world’s fastest 3D printer of micro- and nanostructures. It makes three-dimensional objects smaller than the width of human hair quickly with maximum resolution.

For example, the printer can create a miniaturized spacecraft in less than one minute. Based on innovative laser lithography method, this system increases the printing speed about 100 times. It leverages a technology similar to that for scanning units of CD and DVD drives and laser shows. Called the galvo mirror system, a laser beam is reflected off rotating mirrors for rapid and precise laser focus. In order to achieve their direct laser writing technique, their 3D printing method relies on two-photon polymerization.

Photonics research looks at using higher performance circuits instead of conventional electronics. Drawing from this progress, Nanoscribe’s printer can reach more than five terabits per second to print polymer waveguides. Two photon polymerization works sort of like when you take a magnifying glass and use it to magnify the sun to ignite a piece of paper. Ultra-short laser pulses polymerize photosensitive materials and create the desired self-supporting micro- and nanostructures. Printing three-dimensional objects in such incredibly fine detail opens up many areas where it could be useful ranging from defense through to medicine. For biomedical technology or nanotechnology, the 3D printer could be used to create tailor made construction parts. The printer could for example create biological tissues by printing scaffolds that living cells to which attach themselves.

From a security perspective, this means it could have potential for research in defense against chemical and biological weapons. It also has a lot of potential for defense advanced materials development. Last year, researchers at the Vienna University of Technology also announced a key breakthrough in accelerating the speed of high-precision-3D-printer with nano-precision.

So, what does this all mean?

Well, for me, it’s better to not say anything and let them think you are a fool, rather than open your mouth and remove all doubts. It also means that there will be an explosion of epic proportions for the backyard, garage size, home, or student engineers or developers to open their minds and demonstrate what can be done with a little thought and the right equipment. Toffler was correct about “Future Shock” (Toffler argued in the 60’s that society is undergoing an enormous structural change, a revolution from an industrial society to a “super-industrial society”). This change overwhelms people, he believed, the accelerated rate of technological and social change leaving people disconnected and suffering from “shattering stress and disorientation”—future shocked.

My stress levels are ok and I’m not disconnected, but, I am shocked at how fast this area of development has come in 24 months.

Brian is a digital prepress and print specialist with over 20 years of experience. Certified by Apple and Adobe he has been studying and reporting on technological advancements from 1987 till present and can be reached at graphicfxonline.wix.com or email: [email protected]

This article is written from the gathering of information from OEM websites as well as trade reviews. All names or models mentioned are property of their respective owners.