By Ben Freund

If you haven’t already heard, 3D printing is one of the hottest developing technologies coming to market. One of the biggest questions about it—for readers of PrintMediaCentr, especially—is how 3D printing will impact the traditional print industry. I’ll cover the argument in favor of 3D printing becoming a tool for traditional print shops, explore some of the potential perils 3D printing has to face in the next few years, and share the most exciting recent developments in the world of 3D printing.

3D printing covers a range of technologies from high-end industrial machinery to living-room-ready consumer appliances. Typically these machines operate by creating layer after layer of a material such as plastic, slowly creating a complete product based on a digital blueprint. That product could be a simple as a spare part or child’s toy, or as complex as a customized prosthetic limb or a car body.

The process is called “additive manufacturing,” and it has the potential to create a shift in the manufacturing industry similar to the shift the print industry underwent in transitioning from offset to digital. But besides including the word “print,” does 3D printing have anything to do with 2D print shops?

I’m skeptical, and you might be too. But one man isn’t, and he’s become an evangelist to the cause of using the resources of the 2D print industry to take advantage of the potential of 3D printing technology.

First, Print a Pitcher. Then, Drink the Kool-Aid.

John Hauer believes that 2D printers have the infrastructure and experience to deal with the demands of the coming 3D printing market in a way that typical manufacturers—like injection molders and machine shops—do not.

John’s argument—which you can learn more about at his site, 3D4Printers—can be reduced to two important points.

First, the process of 3D printing is familiar to 2D print shops:

First, the process of 3D printing is familiar to 2D print shops:

“With 2D (digital) printing, the workflow looks like this:

File created → file submitted to print device → file is printed → item is finished (bound, etc.)

The workflow for 3D printing is very similar:

File is created → file is submitted to print device → file is printed → item is finished (decorated, etc.)”

Second, the physical infrastructure and business model of print shops gives them a big advantage in addressing the needs of consumers:

“What hasn’t been developed yet is the retail side of 3D print… [Traditional manufacturers] are not geared toward consumers. They don’t have retail locations, they don’t market to consumers, and they typically don’t have the business model or point-of-purchase systems to deal with small consumer transactions. Who does have that kind of infrastructure? Traditional printers, office supply stores, and shipping giants… They are located in retail areas, are used to dealing with and educating consumers, and have the ability to handle and process a lot of small orders.”

That’s the theory in a nutshell, ignoring all the sticky details of implementation—although you can catch up on some of those in Hauer’s interview with a pioneering 3D print shop owner.

If Hauer is right, traditional printers would be wise to keep an eye out for opportunities to join the revolution that President Obama predicts will take place in the manufacturing industry. So enjoy this quick rundown on the pitfalls and promises the technology will be dealing with in the next few years.

The Pitfalls: What Can’t You Print?

Besides determining the logistics of a brand new industry, there are a few unique problems that are currently threatening 3D printing. Here’s two.

Printable Weapons: You’ve probably heard rumors of a printed assault weapon being made. It’s not quite true: Nobody has yet 3D printed any kind of functional gun. But they have successfully printed some parts, and there are several groups working on finishing the job.

There are also groups—including the U.S. government—actively trying to make such efforts illegal. New regulations are being drawn up, new ways to get around them are being covertly developed, and what will happen next is unclear, but there is a possibility that the political ramifications of 3D printing will have a strong effect on the industry in the future.

Copyright: When you’re talking about literally making perfect copies of objects, the subject of copyright is going to come up. But this isn’t just about the product, it’s about the process. Disney may not be happy if somebody makes their own plastic Mickey Mouse, but that’s nothing compared to the consequences of violating patents related to the creation of 3D printers themselves.

There are patents for molding heated materials, for smoothing rough edges, for using soluble materials to support the creation of durable final products, and on and on. Put together, these patents mean that while we might have the technology for cheap, efficient, quality 3D printing, we might not be legally allowed to use all those technologies in one machine. Yet.

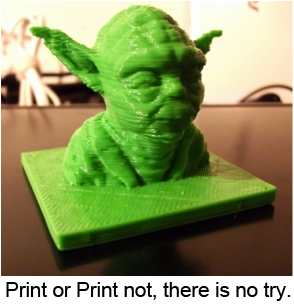

The technology to make Yoda’s head, here, into a polished bust instead of a lego-like model, is patented by Stratasys. Any non-Stratasys printers will not be allowed to provide the same ‘finishing’ process… however, in this case at least, clever hobbyists have found another solution. Patents will slow the development of 3D printing, but the tremendous amount of entrepreneurial interest in the technology will keep finding ways around them.

The technology to make Yoda’s head, here, into a polished bust instead of a lego-like model, is patented by Stratasys. Any non-Stratasys printers will not be allowed to provide the same ‘finishing’ process… however, in this case at least, clever hobbyists have found another solution. Patents will slow the development of 3D printing, but the tremendous amount of entrepreneurial interest in the technology will keep finding ways around them.

The Promises: What Can You Imagine?

Okay, let’s go blue sky. What are some of the amazing things being done with 3D printing today?

The Printed Body: It may never be cheaper to use a 3D printer for mass production, but for personalized objects it can’t be beat. Prosthetics, for example, are very expensive to make and must be customized to fit their users. 3D printing is making that faster and cheaper, whether it’s for artificial limbs, replacement ears, or even human skulls.

Vinyl Music Piracy: File sharing revolutionized the music industry in the 21st century. Now it can revolution the music industry of the 20th century: 3D printers are so accurate they can create working copies of vinyl records.

Make It By Hand: Here’s a fun project: The 3Doodler, a “3D Printing Pen” that allows users to create images and sculptures by “writing” in thin air with plastic. Take that, spin art!

Print and Wear: From the designer of Lady Gaga’s bubble dress comes the first 3D printed dress.

Sustainability in Three Dimensions: The print industry is all about keeping green and eliminating waste. There’s no reason that should change: The Filabot recycles unwanted plastic into usable printing material.

This is a guest post by Ben Freund on behalf of Xcel Products, an industry leading supplier and converter of adhesives, synthetic paper, and other flexible substrates for packaging and retail advertising solutions.

3 Responses

Ben,

3D printing has the chance to revolutionize all manufacturing. As you pointed out, customization would be simple. No need to make expensive molds and set up assembly plants.

I relish the thought of being able to reproduce all my old vinyls that are scratched, worn, and no longer available.

Sad that the government is already looking at ways to limit the creative use of this exciting new medium.

Cheers,

Marc

Braintree Printing in Massachusetts is one of the first to invest in 3D printing while offering traditional commercial printing services. http://www.prweb.com/releases/braintprint3Dprinter/201302/prweb10473734.htm

Sorry it took me so long to reply to you guys!

Marc, I hear there may be some new legal challenges to some of the more restrictive patents that are holding the technology back.

Dave, hope it pays off!