Last week a Press Release came through my inbox from HP announcing “Emerald Packaging, Inc. had signed a launch agreement for the HP Indigo 20000 Digital Press, enabling the company to enter new markets and offer its customers the advantages of digital printing.” Ok, cool, nice for them… but not something I would normally write about… but then I noticed this ” The company will form a joint venture with OEC Graphics of Oshkosh, Wis., leveraging OEC’s design and branding capabilities to head the sales and marketing of digital printing.” and I became very interested in what was going on here!

With the help of Porter Novelli, I was able to send a few questions over to Kevin Kelly, CEO of Emerald Packaging, Inc. and dig a bit deeper into this partnership and how it came about…

Q1: Tell us a little about Emerald Packaging:

Q1: Tell us a little about Emerald Packaging:

KK: We are a 50-year-old, family-owned flexible packaging company that has traditionally focused on food packaging, including dried fruit and nuts, fresh salad, fresh-cut carrots, and microwavable pouches. Our sales are over $85 million. We print, make premade bags and pouches, laminate, and laser microperforate as well as produce roll stock with premade zipper.

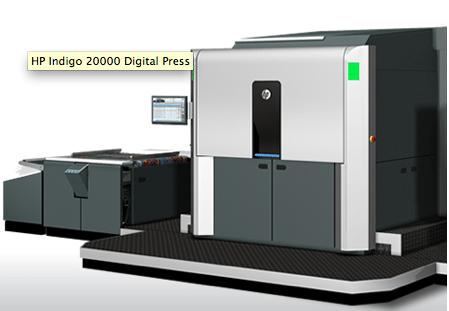

Q2: Why the HP Indigo 20000 and did you have clients in place with a need this press fulfilled, or was the purchase based on expanding your printing possibilities and finding clients after?

KK: I believe the HP Indigo 20000 is the best digital press on the market – really the only digital press for flexible packaging and is likely to be the only one for some time. The print technology has been proven to work for labels. I also believe that HP has a commitment to servicing the press, which is important when you take on a new product like this.

We have a combination of customers interested in this, some existing and some new. I do believe it will allow us to expand our capabilities in our core food markets, by allowing shorter, high quality, customized print runs. The quality alone I think will open up new markets including candy, coffee and cosmetics.

Q3: Congratulations on your partnership with OEC Graphics. How did this strategic alliance come about and how did you get around the competition factor?

KK: OEC is not a printer. They provide brand creation, design and prepress services as well as make printing plates. They don’t print so there is no overlap there. Since so much of what drives the digital print process is the front end prepress work, it made sense for us to partner with a company that already had expertise in the area. OEC has an excellent reputation in this area, and has been a supplier of ours for several years whom we greatly trust.

The press will locate there because they already had a concrete pad in place from the days when a previous building owner had an offset press in the building. We also believe that the press will show better in a less industrial space. We have a manufacturing building, they have a warehouse. Also given the construction of their building, it will be easier to control heat and humidity, essential to success for digital. Emerald will still own the press and provide the press operator as well as the maintenance.

The press will locate there because they already had a concrete pad in place from the days when a previous building owner had an offset press in the building. We also believe that the press will show better in a less industrial space. We have a manufacturing building, they have a warehouse. Also given the construction of their building, it will be easier to control heat and humidity, essential to success for digital. Emerald will still own the press and provide the press operator as well as the maintenance.

Q4: My background is in print buying, so I am curious what the workflow process would be for a project that would fall under the partnership, and ultimately who is responsible for my job?

KK: The artwork would go prepress for art manipulation, then onto the press itself. We are forming a partnership which will have a name distinct from the two companies most likely. But whatever the case, both companies will stand behind the work. Since we will be housed at OEC, less than a mile from Emerald, the two companies will work hand in glove. If the print is passed on to Emerald for final production, obviously we are responsible for lamination, pouchmaking and slitting the rolls.

Q5: I know you just made the announcement, but fast forward a year from now and if everything you hoped for falls into place, what has this press and this partnership achieved for Emerald and OEC?

KK: We will have moved into a new, profitable print category.