by guest blogger and PMC contributor Ben Freund

by guest blogger and PMC contributor Ben Freund

My last guest blog briefly mentioned that a technology was being developed to allow for printing of simple computer chips like RFID tags using metallic inks. The result would be computer chips produced so cheaply and on such flexible substrates that they could be integrated into almost any kind of product or package—posters, clothing, food, medicine.

Let’s take a closer look at what is possible when cheap, printable electronics become commercially available. We’ll take a quick look at how the technology works before moving on to the fun bits—the potential applications.

How To Print A Circuit

The key ingredient is semi-conductive inks, printed in layers to apply all the elements of a complete circuit. In the case of RFID tags, the most expensive barrier to mass production is attaching the relatively inexpensive printed circuit to the more complex etched antenna which powers the circuit and allows it to send and receive data.

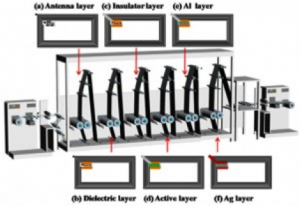

Korean scientists have developed a technique for using roll printing to apply layers of semi-conductive ink, allowing the antenna—and many other kinds of electronic elements—to be printed directly onto substrates rather than produced and attached separately.

Not so different from a traditional offset printer, is it? Combine this technique with inks made from graphene rather than using silicon to create chips, and the result is cheap, flexible, RFID tags, or batteries, or memory storage…

So What Can It Do?

Almost anything! But here are a few interesting inventions that are either already possible or currently in development.

Smart Packaging

QR codes and RFID tags have very limited memory, and that memory can’t be rewritten. At best, they can link to an external resource that houses more information. More advanced printable electronics will change that.

Just last month, Thin Film Electronics ASA revealed the first prototypes for integrated printed electronic tags with sensors, rewritable memory, and programmable logic. The result is packaging that can sense changes in temperature and record these events as they happen.

Spoiled food or compromised pharmaceuticals can be detected on an item-by-item basis, and information about the product’s place of origin and circumstances of manufacture can be recorded and displayed. Until now, such intelligence has been too expensive to implement on individual disposable goods.

Stealth Packaging

Beyond purely practical applications, printable electronics have tremendous potential for marketing. Indeed they have for many years, but there’s been a lack of incentive to commercialize the technology. However, necessity is the mother of invention, and in England at least one industry may be seeing the value of investing in printable electronics.

Specifically, the tobacco industry is facing legal pressure that may soon require cigarettes to be as blank and bland as possible to negate any advantage marketing may have in attracting new smokers. That’s an advantage cigarette manufacturers would prefer to cling on to no matter the letter of the law, and one potential solution is using printable electronics to create packaging that remains bland on the shelf, but comes to life when purchased by the consumer.

When the cigarettes are out of their packaging and activated by touch, a printed battery could activate the box, causing it to light up or activate ‘invisible’ inks. The same technology could be used for magazine covers, greeting cards, and other products that benefit from novelty rather than evading regulations.

Fighting Forgery

As an added benefit, printed electronics also help to fight forgeries. That’s a concern for cigarette manufacturers as well, another reason why the industry might choose to pioneer the technology, but that anti-copying measure would be valuable to manufacturers of all kinds of luxury goods, not to mention adding another layer of security to event tickets and other traditional targets of forgery.

It’s not all about the information that can be shared—or concealed. Intelligent packaging can do more than just think; it can act.

Several prototypes have been created for intelligent clothing that promotes the wearer’s wellbeing. For the incontinent, a garment with a printed-on leak-detection network can act as an early alert system to prevent embarrassment.

For those with various hypersensitivity disorders, the InflataCorset from Sensoree detects excited heart rates with its printed electronics system and inflates to ‘hug’ the wearer and calm their nervous system.

And for virtually anybody, intelligent disposable packaging isn’t limited to protecting its own contents, it can also offer direct feedback to the consumer. The most promising potential is for pharmaceuticals that remind patients when to take their doses.

Finally, the ‘power of print’ we all like to play up is closer than ever to becoming literally true as the technology for printable solar panels develops into maturity. At present, the most viable process requires the use of commercially unviable toxic materials, but development efforts continue and in a few years you may be able to use the power of print to, well, power your printer!

This is a guest post by Ben Freund on behalf of Xcel Products, an industry leading supplier and converter of adhesives, blockout paper, and other flexible substrates for packaging and retail advertising solutions.