PMC is thrilled to have Terry Rayner contribute his lean expertise to our community! I met Terry a few years ago when he was the COO of Coastal Printing. I had been a customer there for years before he started, and I was looking to see if Coastal wanted to hook me up with some printing for an event I was going to. We started talking and instantly I knew he was ahead of the game in regard to keeping print relevant. He wasn’t afraid to venture into the uncharted waters of new marketing technologies, or to educate his customers that mobile + print is the future. Often I would come back from a trade show and shoot him a link to something cool I saw and he always followed up.

I have been trying to get Terry to blog for PMC for a long time. Now that he has started his own business and is taking his operational expertise to the masses, I took a shot to ask again and BONUS! he has agreed to send some relevant content our way! Im sure this won’t last too long as his client list grows, so Printers take advantage while you can, and I will come up with ways to try and keep him around!

Not Understanding Value Can Cost Printers More Than Customers

By Terry Rayner

In a previous post on my site I briefly explained “Value” as it is defined in Lean Thinking – this week I want to delve more deeply into the concept and why it is different than “Value-Added.”

Imagine going into McDonalds and hour by hour the price of a Big Mac being priced differently due to the amount they have sold that day (or worst what they expect to sell). The customer (and you) would think this was crazy – so why do so many printers do just this?

Most printers have come to believe that having a high value-add within a selling price is an indicator of a profitable job… and then discounting based on the retaining a certain percentage of value-add (when placed under price pressure). This might be a good idea if most printers really understood their costs, however, from my experience I would say that most printers do NOT understand their costs, because if they did they would refrain from elastizing their selling price (or selling below their costs)!

So… going back to the title of my blog, if you understand value, instead of slashing the selling price to achieve a sale – what we should be doing is reducing costs (or adding value) to win the sale!

A strategy of increasing Value (not value-add) is a winning strategy in printing (or in any business)!

What is this mystical “value?”

“Value is any action that increases the value of the product or service that you are producing (defined as anything that the customer is prepared to pay for).”

Following this thought we should look at the flow of an order and check off what is value and what is not value. Your list would probably start off/look something like this:

- A face to face sales call on the client to shoot the breeze

- A sales call to get the specifications of a possible order

- Driving back from the client to the office to hand off the specs to the estimator

- Writing up the specs to give them to the estimator

- The estimator building the estimate

- The writing up of a letter of quote

- Sending the letter of quote to the customer

- Following up with the customer to see if he/she receive the quote and asking for the order

- …. And so on

When you start to catalog the process of receiving an order from the beginning, to the time it is delivered, you will have a huge list of actions. Once you have the list check off if each action adds value.

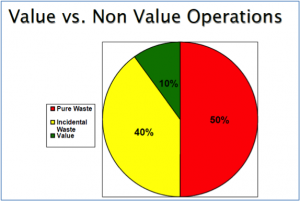

What you will find is that only about 10%-to15% of the actions add value in the true sense. Another 20%-to-30% are necessary, but don’t really add value (when you apply the rule “will the customer pay for this action), the remaining 50% are actions that add no value – but we do them any way!

What you will find is that only about 10%-to15% of the actions add value in the true sense. Another 20%-to-30% are necessary, but don’t really add value (when you apply the rule “will the customer pay for this action), the remaining 50% are actions that add no value – but we do them any way!

Your job now is to go through the 85%-to 90% of the WASTE (Yes these actions are all WASTE – because if they are not adding VALUE they are wasteful action), and reduce them so that value increases as percentage of the selling price!

One way would be to add an on-line order system where the customer can enter their specs, get a price and place an order without interacting with the sales rep. You might say this is a reduction in customer service and that without the personal touch you will not get orders. However, your customers probably will tell you that they would like the convenience of getting a price and ordering any time of the day and getting the price instantly and being able to then place the order! The customer may perceive this as improved customer service!

Now I am not saying that you go out and fire your sales reps – because in this business model the sales rep now has the time to hunt for new business rather than taking orders.

What would you rather be doing? Expanding your business or remaining static and losing customers to your competitors (that are offering alternative improved ways to do business with their customers)?

Look, this is a simple process – rally your team together and do this – then starting eliminating waste! As you do this you will see your costs reduce, making it possible for you to sell at lower selling prices – WHILE STILL MAKING PROFITS!

Look, this is a simple process – rally your team together and do this – then starting eliminating waste! As you do this you will see your costs reduce, making it possible for you to sell at lower selling prices – WHILE STILL MAKING PROFITS!

And BTW – who cares about value-added – at the end of the day it is about profits – make choices based on adding value – not on value added!

And you will see you profits increase…

With over 25 years of print management experience Terry Rayner is a Lean Thinking Guru. Using his blend of customer focused philosophies and continuous improvement methodologies he has led companies through major changes to emerge re-energized. Certified in Lean Six Sigma Processes for manufacturing, office and sales environments he is relentless in his pursuit to eliminate wastes, which increase efficiencies and effectiveness; ultimately leading to higher customer satisfaction and significant profit growth.

Connect with Terry: Getleanthinking.com / LinkedIn / Twitter