The most recent drive towards sustainability motivated many companies to rethink packaging. Popular brands scrutinize the carbon footprints of their products. Packaging received so much attention during the Pandemic that Forbes Designated 2021 – The Year of the Package.

The quest for the most sustainable packaging includes reviews to reduce the environmental impact. The goal is to land on the best combination of product, processes, and carbon footprint calculations.

What prompted this most recent exodus from paper? Is this a temporary paper vs plastic trend like we saw in the 90s or similar to the aluminum vs glass packaging battle influenced by material tariffs enacted in recent years?

There are numerous reasons why companies are now implementing paper packs and moving out of plastic. While the consumer’s voice used to be based on market research and sales, companies now keep their ear to social media to gauge how well they are doing. Consumers use social media for activism, vote for causes close to their hearts, and are loud and clear on social media when it comes to packaging. Consumers today have a direct line of communication with packaging decision-makers.

Once the consumer’s voice is heard, how much is the final packaging design decision influenced by sustainability initiatives and pricing?

The answer is, “it depends on a lot of things, consumer influence, company mission, timing for changes, budget, volume, available technologies, etc.

The approach to packaging decisions related to sustainability can be grouped into three categories.

• Past – Companies traditionally and proactively manage for packaging end use and look at consumer behavior, and how to maximize recycled materials. These companies assume future technology may replace legacy packaging but realize existing packaging and technology should be managed more sustainably. Examples are unbleached paperboard, printed guidance, and the use of increased recycled content in packaging.

• Future – Companies strive for the ultimate sustainable pack and focus on R&D to develop what is deemed to be a long-term solution. The technology may not be perfected, but it is adopted early and improved over time. Examples are plant-based materials and compostable packaging.

• Present – Companies rely on packaging teams and suppliers, driven by leadership to produce immediate and visible impacts. This process may take years in the background on the supplier and R&D side, however, companies with this mindset are prepared to nimbly implement packaging as soon as it is available commercially and meets functional requirements. Examples are paper-based materials and the elimination of difficult to recycle inks or colors.

Moving to paper may seem like a seamless process and easily attainable low-hanging fruit, especially if there is an existing paper-based solution. However, that may not be the case. Some companies naturally land on paper, to avoid the ire of consumers, while other products may lend very well to packaging. Decades of research and development and money get assigned to packaging development on the product and supplier side. There are other factors that influence the decision to move to paper packaging, some are:

- Recycling – certain areas, cities, or regions may landfill paper more often than plastic

- Barrier properties – the product may need protection that paper alone cannot provide

- Structure – fragile products or products with iconic shapes are challenging for paper

- Color – iconic brands may be hesitant or concerned about fading or color matching

- Weight – heavier products may need more paper-based material for strength

- Cost – paper packaging solutions cost may cost more, low volumes increase the cost

- Carbon footprint – energy and water usage to create paper packaging is intensive

- Renewable – the philosophy and process of tree conservation has matured over time

In a nutshell, the decision to switch to paper is based on many factors. The process is not as simple as flipping a switch or calling in a new supplier, it can take decades to eliminate all plastic packaging, realistically, plastic will probably never disappear completely.

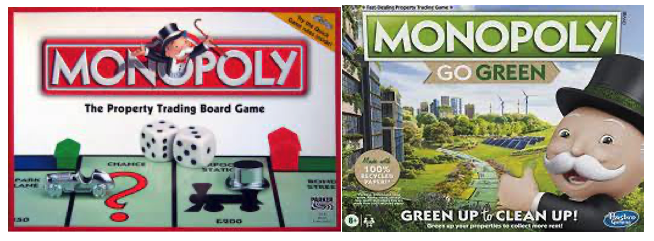

Here are a few before and after examples of early adopters of paper packaging.

According to Packaging World – Hasbro is moving away from plastic packaging by 2022.

Smarties took the opportunity to replace plastic when they rebranded this iconic candy.

Make no mistake, this paper bottle for Johnnie Walker Black Label was quite a feat. To eliminate a plastic lining for a liquid product and provide a striking shelf presence took time, skill, coordination, and energy!

Grocery bags were first made to be reused in the 1960s, unfortunately, the timing of this well-intended bag coincided with the plastic industry’s campaign for consumer convenience.

Soft drink components – Paper rings seemed to be a no-brainer after seeing multiple impactful images of turtles and sea creatures wearing plastic rings. The coordination required new suppliers, testing, redesign, and negotiation.

Camille Corr Chism, CPPL Fellow, has a diverse background in packaging engineering, design, supply chain, project management, and new product introductions. Her experience includes a variety of industries including food, e-commerce, technology, distribution, pharmaceutical, industrial, and automotive. Earning an MS and BS in Packaging, Camille earned a Six Sigma Black Belt (2019), and a lifetime certification as a Certified Packaging Professional in 2006. She was inducted into the IoPP College of Fellows in 2014.

Camille Corr Chism, CPPL Fellow, has a diverse background in packaging engineering, design, supply chain, project management, and new product introductions. Her experience includes a variety of industries including food, e-commerce, technology, distribution, pharmaceutical, industrial, and automotive. Earning an MS and BS in Packaging, Camille earned a Six Sigma Black Belt (2019), and a lifetime certification as a Certified Packaging Professional in 2006. She was inducted into the IoPP College of Fellows in 2014.

Camille is the owner of Indigo Packaging and Consulting. She is the go-to person for all your packaging products and packaging design needs. Connect with her on LinkedIn, LinkedIn Company Page, Twitter @indigopkg, and Instagram @indigopkg

One Response

Out of the world’s man made emissions of 37 billion tonnes of CO2, 5 billion tonnes is emitted from pulp paper making, and that is just a starting point of the emissions (water, sulphur, sulphur dioxide, sulphuric acid, toxins, chemicals, energy and high density forestry forestry issues) do not make pulp paper a sustainable option.

Rich mineral paper made from up to 81% waste marble is a more sustainable option with none of the above issues during manufacture and has many of the benefits required for packaging including waterproof, greaseproof, freezer grade, food-grade, moth and insect resistant, photo-degradable, recyclable with number 2 or soft plastics(as calcium carbonate is a useful additive when recycling plastics.

With synthetics (plastic resins) the growth has been immense, but the industry has not put in place enough infrastructure to recycle enough, to remake or make recycled products.