I just read a relevant post by Greg Cholmondeley “What the heck is a print manufacturer?” In the article Greg examines the difference between a manufacturer and a craftsman along with why choosing to be a manufacturer will make your printing company more successful!

As I read the article it makes me think of two things: Standardization and Automation

Standardization: to make print production a process that is controllable, repeatable and right the first time!

Automation: Using technology to make print ordering easy by removing unnecessary bottlenecks through the use of reducing wasteful steps in the workflow!

As a business manager I would suggest you should be looking at Lean Thinking (Manufacturing) to bring both standardization and automation together to create a business strategy that will differentiate your company’s “go-to-market” position.

Start by taking the time to learn about Lean Thinking. Three good books to get you started are:

- Lean Printing – A Pathway to Success by Kevin Cooper

- Lean Printing – A Cultural Imperatives for Success by Kevin Cooper

- The Lean Turnaround by Art Byrne

I know most of us just want to jump in and make change, however, to make real sustainable change there must be a plan of action and you must understand what you are going to do differentiate your business model to rise above your competition,

From what I can see: Success comes from delivering a profitable product or service, that consumer’s want – at a price that they will purchase it at!

From what I can see: Success comes from delivering a profitable product or service, that consumer’s want – at a price that they will purchase it at!

In Lean it’s simple for the manufacturer to understand how to be successful:

Profit = Price – Costs!

To build a successful product or service one must use this strategy to examine how your products and services are manufactured. And this is where standardization and automation come into play.

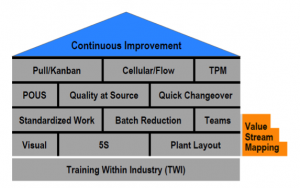

Using the Lean “House of Quality” we build the foundation by learning and training, then adding to the solid foundation by addressing standardization by using the lean tools: 5S, Visual and Plant layout.

Standardization is how you control costs!

And once costs are in line, your business can then start to look towards innovation!

Lean brings with it innovation as it challenges you and your team to stretch yourselves. You create teams and they share their ideas – ideas that will change your business in a positive way!

Automation runs parallel to standardization – Look at your system-wide business software(s). Do all the modules talk to each other, or are they in Silos? Does the software deliver information to you that will allow you to improve your business? Does it let you know your average make-ready times and production speeds, does it throw out flags when standards are not met? Is there duplication of tasks? How much keying takes place?…

Automation runs parallel to standardization – Look at your system-wide business software(s). Do all the modules talk to each other, or are they in Silos? Does the software deliver information to you that will allow you to improve your business? Does it let you know your average make-ready times and production speeds, does it throw out flags when standards are not met? Is there duplication of tasks? How much keying takes place?…

…The list continues. I am sure you see my point and where I am going with this.

I challenge you to get reading and to start asking questions of your current business model and then to start making changes that will set you upon the path towards success!

With over 25 years of print management experience Terry Rayner is a Lean Thinking Guru. Using his blend of customer focused philosophies and continuous improvement methodologies he has led companies through major changes to emerge re-energized. Certified in Lean Six Sigma Processes for manufacturing, office and sales environments he is relentless in his pursuit to eliminate wastes, which increase efficiencies and effectiveness; ultimately leading to higher customer satisfaction and significant profit growth.