By Guest Blogger Ben Freund

A recent survey by DuPont Packaging got me thinking about the future. The first part of the survey asked packaging professionals from across the world about the most important priorities affecting the industry – cost, sustainability, convenience, shelf impact, and so on. But what really caught my eye was the second part of the survey that asked the same professionals what they thought would be most important ten years from now, in 2022.

The answers were surprisingly different. While cost is king in 2012, sustainability looks to be the biggest concern by 2022. Today integrating merchandising strategies in the packaging process is essential, tomorrow trackability and anti-counterfeiting measures may be the next major challenge.

A lot can change in just a few years, and that’s doubly true for food packaging. Not only is it one of the most competitive and fast-changing markets, it’s also subject to considerable attention from consumers who easily associate innovation with quality but are vocally critical of waste – consider last month’s outraged reaction to a grocery chain selling pre-peeled bananas packaged in Styrofoam and plastic.

Here are a few examples of changes we might expect to see in food packaging and printing in the near future.

Rise of the Private Label

Private label foods are one of the few industries to flourish in the recession. While consumers might once have winced at the thought of buying the blandly packaged and blander-tasting store brand products, the penny pinching necessitated by the recession gave millions a reason to give these cheaper alternatives to national brands a second look. What they discovered was that the quality of private label foods has significantly improved in recent years while the prices have remained comparatively low.

Private label foods are one of the few industries to flourish in the recession. While consumers might once have winced at the thought of buying the blandly packaged and blander-tasting store brand products, the penny pinching necessitated by the recession gave millions a reason to give these cheaper alternatives to national brands a second look. What they discovered was that the quality of private label foods has significantly improved in recent years while the prices have remained comparatively low.

That’s a big opportunity for retailers, who can reap higher profit margins from private labels compared to branded products. It’s also a big opportunity for the packaging and printing industry, because presentation of private label foods is and will continue to be one of the most important aspects of distinguishing one chain’s private label offerings from another – you may be surprised to learn that most private label foods like cereals, frozen pizzas, and sauces are made by independent companies and then packaged to suit specific retailers.

Few consumers are aware of this and even for those that are it’s difficult to determine whether the private label product at Grocery Chain A is supplied by the same food manufacturer that serves Grocery Chain B. It’s an opportunity for chains to increase customer loyalty by being the only apparent source of a favorite private label product. That means what’s on that label – or box, or wrapper – becomes an important signifier of quality and distinction. Private labels are becoming big business, and so is the packaging and printing surrounding them.

Recycle with Your Mouth

New packaging gimmicks appear all the time; whether it’s a bold reinvention of the humble cereal box or a resealable in-package answer to the chip clip. But they’re just that – gimmicks. For the kind of change that can really reinvent the industry, we need to think less about eye-catching shapes and novel features and look at new, sustainable materials.

Recyclable materials are a good step, but they rely on active participation by informed consumers. The next wave is packaging that is completely biodegradable, compostable – and edible! The technology isn’t likely to take over grocery stores just yet, but in ten years it may be a common sight.

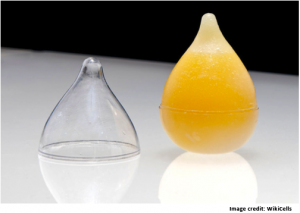

Inspired by the skin of a grape, WikiCells is one of the most intriguing ideas hitting the marketplace this year. The primary casing surrounding the food or liquid is made of flavored food particles held together with calcium ions and algae extract. It doesn’t dissolve in water and can be washed before consuming it, skin and all, like any fruit or vegetable. The second, harder layer could be used to protect the product when shipping, and while it may not be edible it would be made of organic, compostable material like tapioca. The creator of WikiCells, Harvard professor David Edwards, is hoping to have products in stores by late 2013.

But while WikiCells are fascinating, they may not offer much to the packaging industry any time soon. For that, consider MonoSol’s Vivos line of edible, water-soluble films. This packaging technology is already available for commercial use by existing converting technologies to package pasta, soup, instant coffee, and other foods meant to be submerged in hot or cold water. The flavorless transparent bag goes in the water along with the food and dissolves, saving production time and eliminating waste. MonoSol believes the only obstacle to widespread use of their new films is the psychological barrier consumers may have against “eating plastic,” but that barrier has already been breached for products like pharmaceutical pill coatings and breath strips.

Inspiration from Across the Ocean

Gimmicks may not be the future – but they sure are fun. For inspiration or just entertainment, it’s interesting to take a look at packaging trends in Japan, a country with a strong first-world economy but a distinct culture that embraces novelty in design to fuel point of purchase impulse buys at ubiquitous vending machines and convenience stores.

Part snack, part dog, this little fellow begs candy customers to “take me with you.” Just a simple perforation of a standard cardboard box, and suddenly the product adds the appeal of a cuddly puppy to the already irresistible attraction of chocolate.

Why did it take so long to think of this? This bottle of water has a hinged, rather than detachable, cap that will never get lost.

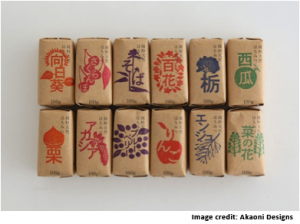

Slick design and innovation isn’t the only way to make an impression. These packages for flavored honey use unbleached brown paper and rubber stamps to give a handmade feeling to a mass-market product.

Slick design and innovation isn’t the only way to make an impression. These packages for flavored honey use unbleached brown paper and rubber stamps to give a handmade feeling to a mass-market product.

What other trends can we expect to emerge from Japan? Well, the creator of the Vivos water-soluble film was recently acquired by a Japanese company, another sign that the technology is ready to take off. The “psychological barrier” against eating packaging may be weaker in Japan, where for over a century edible rice paper has been wrapped around tangerine-flavored candies called Bontan Ame.

This is a guest post by Ben Freund on behalf of Xcel Products, an industry leading supplier and converter of printable plastics and other substrates for packaging and retail advertising solutions.

One Response

This is really innovative and

could solve a lot of problems concerning disposal of non biodegradable materials.