By Terry Rayner

By Terry Rayner

Most of us are familiar with SOP’s (Standard Operating Procedures), however, most of the time these were written by either management or a consultant explaining the way to run a piece of equipment or to perform a task. Then issued to the employees with expectation that they would follow them and all would be perfect!

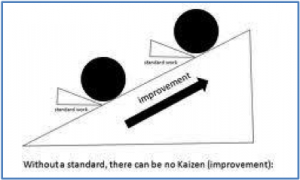

Standard work is not a “Standard Operating Procedure,” as standard work is built from the bottom up (not the top down). It is built by the experts (the people performing the function/task or actions); then (and only then), after the standard work has been built your kaizen teams can review them and work to improve them!

Standard work allows everyone to perform a task the same way, the best way; without waste!

Unlike SOP’s – standard work are living documents – for everyone to use: Leaders, management and frontline employees alike – to use every day! And for us all to improve upon!

Also, in addition to documenting tasks – when used to record workflows Standard work can have times allocated to each step of the task – this way not only are the steps recorded, but there are timeline expectations linked to each task. By adding times to the tasks you are now able to base-line your process and then to start improvement (eliminating wastes)!

Also, in addition to documenting tasks – when used to record workflows Standard work can have times allocated to each step of the task – this way not only are the steps recorded, but there are timeline expectations linked to each task. By adding times to the tasks you are now able to base-line your process and then to start improvement (eliminating wastes)!

Standard work does not stop at equipment operating procedures, it can be used to map out and remind you of critical tasks needed to be achieved on a daily, monthly or yearly basis.

What’s more, because each employee builds their own standard work – the likelihood it will be adhered to is much higher (as they we involved in the building process).

Standard work also sets you up to start cross training (a vital part of the Lean Process). For once there is standard work in place, is is far more easy for another employee to pick up and read the standard, giving them an immediate understanding of the tasks at hand. That is not to say the person being trained will need task specific training or job/education training before they can complete the task, however, he/she will be able to see what is required to achieve the task/function!

Standard work also flows over into visual cues… posting it so that everyone can quickly understand what is needed and what to do when they arrive at a work area.

Standard work also flows over into visual cues… posting it so that everyone can quickly understand what is needed and what to do when they arrive at a work area.

In addition standard work can help you map out your days as you should set out your own standard work. Then use a “to-do list” to maintain your daily progress of tasks and actions.

To make it easy I have a simple form that I use to build standard work. Click here to download it!

Get started! And bring standard work to your business… and continue the journey of implementing lean to give your company a market advantage!

With over 25 years of print management experience Terry Rayner is a Lean Thinking Guru. Using his blend of customer focused philosophies and continuous improvement methodologies he has led companies through major changes to emerge re-energized. Certified in Lean Six Sigma Processes for manufacturing, office and sales environments he is relentless in his pursuit to eliminate wastes, which increase efficiencies and effectiveness; ultimately leading to higher customer satisfaction and significant profit growth.

Connect with Terry: Getleanthinking.com / LinkedIn / Twitter